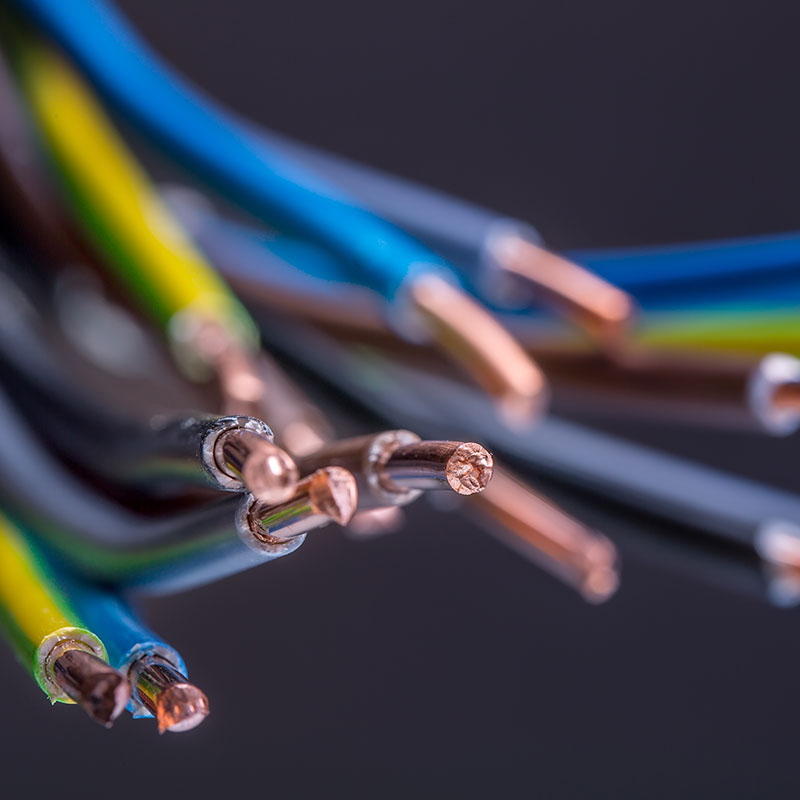

Rubber and Cable Industry

Traditional applications for fine chalks include the rubber and cable industry, as well as other polymer applications.

By incorporating chalk as an inactive filler, rubber and other synthetic polymer mixtures like PVC can be "filled," resulting in a more cost-effective production of rubber products such as molded items, construction profiles, automotive window seals, hoses, conveyor belts, foam rubber insulation, and cables through coating or filling.

For example, in a bicycle tire, even though the rubber compound contains up to 60% rubber, chalk is used as a filler alongside components like carbon black and other additives. Different formulations are possible due to usage, wear, and associated properties such as comfort, grip, and rolling resistance.

Fine chalk is also employed as a filler in the production of various rubber molded articles, including shoe soles. Chalk can enhance durability, dimensional stability, strength, and mechanical properties, thereby improving the final product.

Another advantage of fine chalk in the rubber and cable industry is its ability to reduce product weight. By adding chalk, smaller quantities of expensive raw materials like rubber or plastics can be used, resulting in reduced final weight.

In this context, chalk is one of the most widely used fillers with versatile applications in the plastic processing industry. Modified chalk is also utilized in the production of window profiles or rigid PVC, such as pipes.

Our Fine Chalks:

Microsöhl®

Nordkrone 40®

Nordweiss® (Lägerdorf)

Rügener Schlämmkreide®

Key Considerations for the Suitability of Our Fine Chalks Include:

- the amorphous structure

- the average particle diameter of 2.5 µm

- the particle size distribution with residue-free at 40 µm

- the low moisture content of <0.5 %

- the high filler levels

- the good spraying speeds

- the easy incorporation

- the good elasticity and strength values

- the high values for electrical resistance

- the good mechanical properties

Ceramic Products

Chalk is a crucial component in the ceramic industry, used in mass formulations alongside kaolin and clays, as well as in glazes.

For instance, Söhlder fine chalk Microsöhl® or Rügener Schlämmkreide® is employed in the production of wall and floor tiles, as well as split tiles.

The high purity of our chalk ensures optimal conditions for use.

In accordance with the technological requirements of tile production, we are able to supply chalk in various particle size distributions.

Industrial Fillers

Our fine chalks are processed and used as fillers or carriers in various industrial sectors, both in dry and slurry form.

Chalk products find applications in various industries, including adhesive manufacturing, brake pad production, construction chemicals, plant protection, electrode manufacturing, textile industry, putty production, bitumen products, and the chemical industry, among others.

In these applications, chalk plays a critical role in optimizing costs while maintaining high-quality standards in the manufactured products.

Paints and Coatings

Our slurry chalks find application in the production of paints, particularly in dispersion-bound interior wall paints.

Manufacturers can optimize their paint formulations from both cost and quality perspectives by using chalk as a filler. Light slurry chalks like NORDKRONE 40® and Rügener Schlämmkreide® significantly contribute as cost-effective fillers for formulating interior paints of varying quality levels.

These chalks enhance the opacity of dry paint films and support dispersion. During the slurry process, organic and inorganic impurities are removed from the raw chalks, resulting in high-purity chalks with a high CaCO3 content and a fine particle size distribution in the medium range of 2 µm, ensuring a high degree of whiteness. Amorphous white chalks have been a crucial component in premium-quality wall paints for years.

Flooring

Chalk is a vital and environmentally friendly filler in the production of floor coverings like linoleum.

Chalk is not only a natural and abundant mineral, making it a sustainable raw material source, but it's also a non-toxic filler with no adverse effects on human health.

Additionally, chalk contributes to carbon emission reduction by providing an alternative to synthetic fillers like talc or silicates in linoleum production. Chalk enhances the floor covering's lifespan and resistance to wear and tear.

Linoleum, known for its durability, natural components, and ability to enhance color and design, is a popular choice for flooring in various buildings. Chalk plays a significant role in manufacturing this material, which has been successfully used for over 150 years.

Chalk distribution with expert advice –

Experience and knowledge make the difference.